Musashi Auto Parts diversifies into EV parts, targets 2W, 3W OEMs

Japanese Tier-1 components maker, which is a key supplier of transmission gears, shafts, and differential assemblies to leading OEMs in India, is diversifying into EV parts and aims to tap demand from the fast-growing electric two- and three-wheeler industry.

The rapid growth of the Indian electric vehicle industry, particularly the two- and three-wheeler segments, is seeing a number of component suppliers bet big on this zero-emission vehicle sector. The latest is Japanese Tier-1 component supplier Musashi Auto Parts India (MAP-ID).

MAP-ID, which is a leading supplier of transmission gears, shafts, and differential assemblies to IC-engine two- and four-wheeler OEMs in India, is diversifying into the EV components market. Cognisant of the growing demand from the electric two- and three-wheeler segments, both of which have registered record sales in CY2024, MAP-ID is bullish about its new product strategy.

Earlier this year in June, MAP-ID commenced mass production of e-axles for electric two-wheelers at its plant in Bengaluru, Karnataka. The company has set up a joint venture – Musashi Delta e-Axle India – with the Netherlands-based Delta Electronics and Japan’s Toyota Tsusho to manufacture and sell e-axles for two-wheeler EVs.

MAP-ID is supplying its EV-specific products to two anchor customers – Coimbatore-based EV startup BNC Motors and Bengaluru-based Emobi. While the former is implementing Musashi’s e-axle into its Perfetto e-scooter targeted at personal buyers, the latter is leveraging Musashi’s technology to power its electric two-wheelers for last-mile delivery operations.

At present, the company’s Bengaluru plant has an e-axle manufacturing capacity of 100,000 units per annum but, depending upon the market trajectory and evolution of EVs in India, MAP-ID aims to double the capacity by CY2026. It is eyeing production and sales, equivalent to a million units per annum, by CY2030, in line with the government’s ambition of electrifying nearly 80% of the Indian two-wheeler market by the turn of the decade.

Naoya Nishimura, CEO, MAP-ID: "We currently have one line each for e-motor and e-axle manufacturing in Bengaluru and will expand them further, ensuring that production levels align with the evolving needs of the industry.”

Naoya Nishimura, CEO, MAP-ID: "We currently have one line each for e-motor and e-axle manufacturing in Bengaluru and will expand them further, ensuring that production levels align with the evolving needs of the industry.”

In an exclusive interaction with Autocar Professional, Naoya Nishimura, CEO, MAP-ID, said, “We anticipate strong demand for both ICE and EVs in India’s two-wheeler market in the coming years, and as a strategy, we will expand our manufacturing capacity for EV components to tap into the additional volumes. While we currently have one line each for e-motor and e-axle manufacturing in Bengaluru, we will expand them further, thus ensuring that the production levels align with the evolving needs of the industry.”

According to Nishimura, while a growing domestic market will continue to create demand for both ICE and electric two-wheelers in India, the sub-100cc two-wheeler segment is the one which will transition to EVs the fastest. ICE two-wheelers, on the other hand, will likely see demand in the premium or high-capacity motorcycle segment, as per Nishimura.

By CY2030, MAP-ID plans to expand production at its Bengaluru (left) and Bawal plants to 8 million units from the existing 7 million units per annum.

By CY2030, MAP-ID plans to expand production at its Bengaluru (left) and Bawal plants to 8 million units from the existing 7 million units per annum.

Strategic goal to become an end-to-end EV systems supplier

At present, two-wheeler supplies comprise 60-70% of MAP-ID’s total business. The Tier 1 supplier provides its locally manufactured, forged-and-machined transmission gears and shafts from Bawal (Haryana) and Doddaballapur (Karnataka), to two-wheeler OEMs, including Honda Motorcycle & Scooter India, Suzuki Motorcycle India, and India Yamaha Motor, among others. Its passenger vehicle business comes from key customers such as Maruti Suzuki India, Honda Cars India, and Toyota Kirloskar Motor, among others.

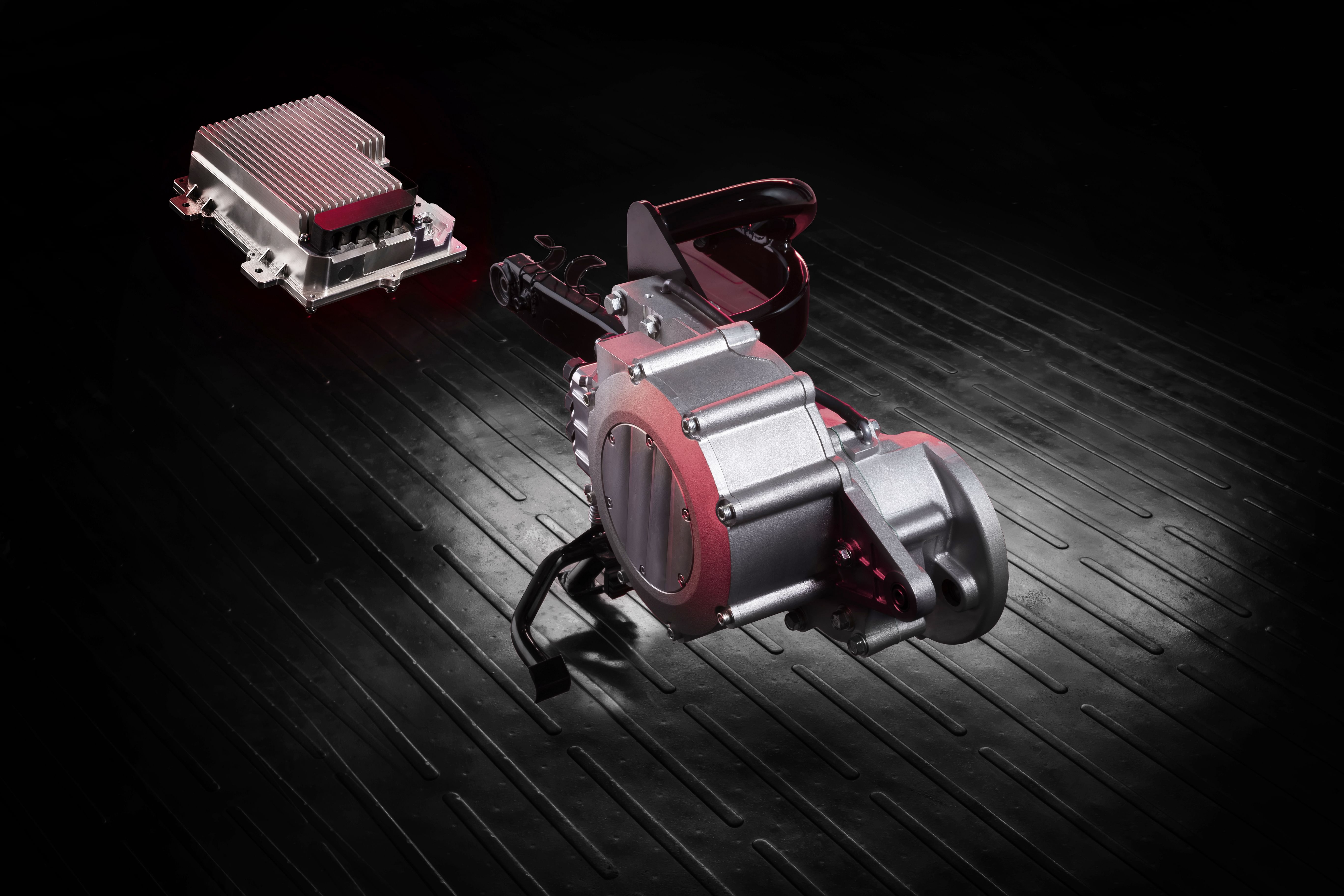

Now, with its foray into EV components, the company aims to become an end-to-end systems supplier. As a result, MAP-ID is strengthening competencies to develop EV components and is targeting increased revenues from its high-value EV parts. Its locally-manufactured e-axle too is an integrated system that comprises a gearbox, e-motor, and an electric drive unit – all packaged into a compact and lightweight assembly.

Musashi Delta e-Axle India, MAP-ID’s JV with Delta Electronics and Toyota Tsusho, will manufacture and sell e-axles for two-wheelers.

Musashi Delta e-Axle India, MAP-ID’s JV with Delta Electronics and Toyota Tsusho, will manufacture and sell e-axles for two-wheelers.

“While we have already developed a robust portfolio of ICE products and can leverage several tangible and intangible assets, we will develop more products and strengthen our R&D capabilities when it comes to EVs,” said Nishimura.

The company has recently collaborated with Bengaluru-based Indian battery-technology startup Log9 Materials, and integrated its e-axle with the latter's locally-manufactured li-ion batteries to create an integrated powertrain for electric two- and three-wheelers in the domestic market. Based on its core competencies of forging and machining, the company is betting big on the EV business as a new opportunity to tap into for future growth.

Going forward, MAP-ID is bullish about registering strong double-digit growth of nearly 20% over the next five years. By CY2030, it envisages a production volume growth of around 14% to 8 million units from the existing 7 million units across its two plants in Haryana and Karnataka. Over the next three to five years, the company plans to make investments to the tune of US$ 80-90 million (Rs 666 crore to Rs 750 crore) to expand capacity and also enhance competencies in India.

ALSO READ: Indian e2W OEMs sell 1.07 million units in January-November 2024, up 37%

Bajaj Chetak is best-selling e2W in first three weeks of December

Electric 3Ws maintain double-digit growth in November, 11-month sales at record 631,000 units

RELATED ARTICLES

Hyundai walks the eco talk with biogas plant, material recovery plant in Gurugram

Operational since October 2022, the facility targets sustainable waste management in Gurugram by undertaking scientific ...

Rajiv Bajaj reappointed MD and CEO of Bajaj Auto for five-year term

Bajaj Auto’s Board of Directors has approved the re-appointment of Rajiv Bajaj as the company’s MD and CEO for another f...

JSW MG Motor launches Comet EV Blackstorm edition

The key highlights of the Comet EV Blackstorm, which is now the top-end variant, are its ‘Starry Black’ exterior along w...

24 Dec 2024

24 Dec 2024

6714 Views

6714 Views

Autocar Professional Bureau

Autocar Professional Bureau