Johnson Controls’ new crash test facility enables standardised safety testing of seats globally

Automotive seating company Johnson Controls has opened its new state-of-the-art crash test facility at its Automotive Seating headquarters in Plymouth, Michigan, USA.

Automotive seating company Johnson Controls has opened its new state-of-the-art crash test facility at its Automotive Seating headquarters in Plymouth, Michigan, USA.

The 6,000-square-foot facility houses a Seattle Safety ServoSled that allows the automotive supplier to offer the most accurate, standardised safety testing of seats globally through collaboration with its other testing facilities located in Burscheid, Germany; Changchun and Shanghai, China; and Yokohama, Japan.

"The investment in this new North American crash test facility reinforces our commitment to innovation and technology as well as the safety of our products," said Jeff Williams, group vice-president and general manager of Johnson Controls Automotive Seating's global Complete Seat and Supply Chain group.

"There are only 44 ServoSleds worldwide and only 10 in the United States. Johnson Controls has one of the largest sled testing networks globally," according to Williams.

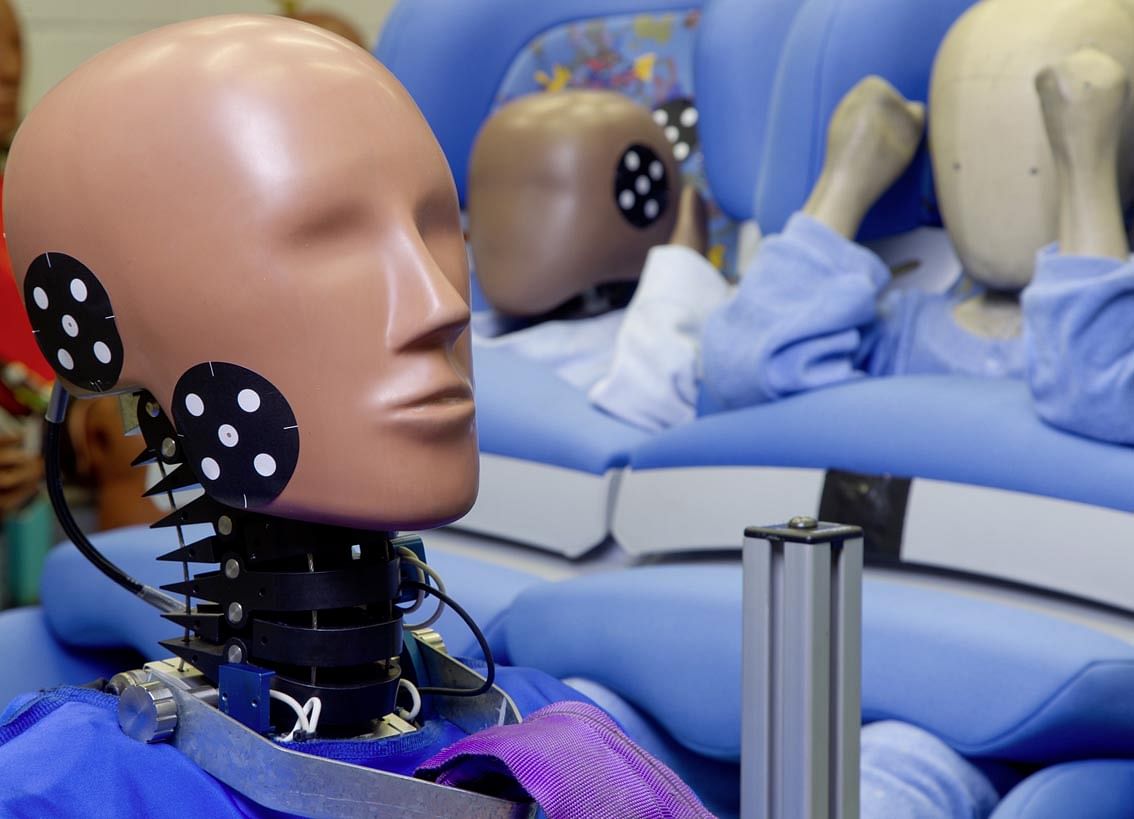

One of the digital BioRID mannequins used in Johnson Controls crash test facility at its Automotive Seating HQ

The new lab addresses increasingly stringent and precise governmental seat safety specifications as well as its customers' expectations for a testing environment that meets evolving industry standards.

As vehicle production is globalised, Johnson Controls is positioned to consistently deliver global engineering, product development and validation to meet those needs. Global collaboration on validation methods and equipment ensures that similar results are achieved regardless of the testing location.

The new sled is a closed-loop system that allows the company to monitor in real-time what is happening to the seat or seat component as a test is being run. Test results from the new equipment are extremely accurate, repeatable and predictable. Such high-precision tests enable engineers to gain insight into the stability and dynamic behavior of seat structures, evaluate the effectiveness of head restraints in preventing whiplash, and find potential areas for improvement.

Photograph: A whiplash test is run in Johnson Controls’ new crash test facility in Plymouth, Michigan. The new sled is a closed-loop system that allows the company to monitor in real-time what is happening to the seat or seat component during testing.

RELATED ARTICLES

Hyundai walks the eco talk with biogas plant, material recovery plant in Gurugram

Operational since October 2022, the facility targets sustainable waste management in Gurugram by undertaking scientific ...

Rajiv Bajaj reappointed MD and CEO of Bajaj Auto for five-year term

Bajaj Auto’s Board of Directors has approved the re-appointment of Rajiv Bajaj as the company’s MD and CEO for another f...

JSW MG Motor launches Comet EV Blackstorm edition

The key highlights of the Comet EV Blackstorm, which is now the top-end variant, are its ‘Starry Black’ exterior along w...

13 Aug 2014

13 Aug 2014

8713 Views

8713 Views

Autocar Professional Bureau

Autocar Professional Bureau