Bosch says diesel can also be clean; BS VI by 2020 in India challenging but achievable

Global component and technology services supplier Bosch, which is looking to offer clean, safe and affordable technology to India, has provided a counter-argument to the popular notion in India that diesel is dirty.

Global component and technology services supplier Bosch, which is looking to offer clean, safe and affordable technology to India, has provided a counter-argument to the popular notion in India that diesel is dirty. The fact is that diesel can be clean.

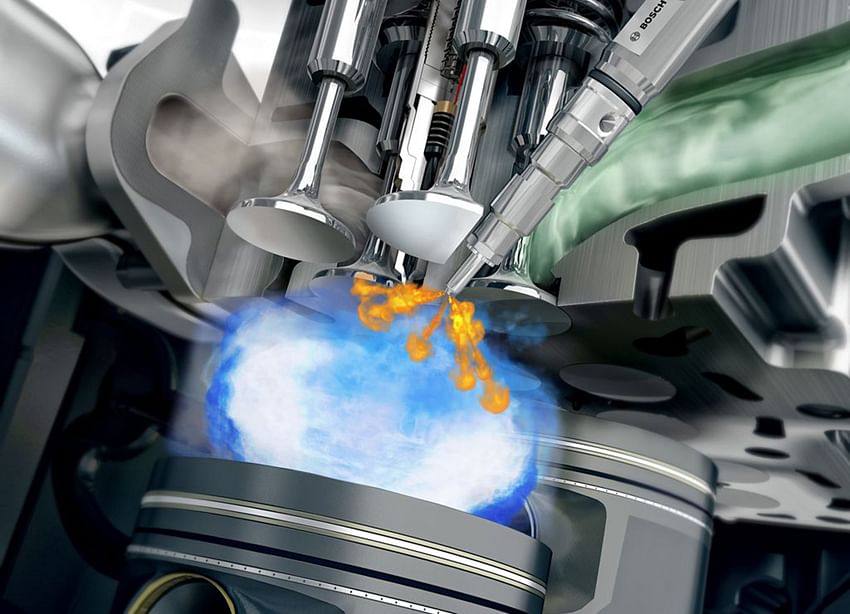

Speaking at a media meet in Noida today, Dr Markus Heyn, member of the Bosch board of management, said: “Common-rail technology established vehicles powered by diesel engines as fuel-efficient and fun to drive. Today, despite, or perhaps because of all the discussions in India on the topic of diesel, I want to especially emphasise that diesel is not only efficient, but also clean. Diesel plays an important role for mobility and climate protection. Since diesel engines emit 15 percent less CO2 than comparable gasoline (petrol) engines, diesel-powered vehicles will play a crucial role in meeting CO2 targets.”

“With BS VI, there will be no difference between diesel and petrol in PM emissions, and only a minor difference in NOx levels. However, combining these two in the case of diesel – low CO2 emissions as well as low particulate and NOx emissions – is a demanding engineering goal for the local automotive industry.”

Referring to the high level of air pollution in New Delhi and NCR, Dr Heyn said: "The diesel engine has the potential to be an air-cleaning machine. Thanks to its modern filters, it can output cleaner air than it takes in, especially in areas with high levels of particulate emissions – and this while emitting less CO2 than other combustion engines. However, we must also make sure that quality and safety standards can be met through proper validation under conditions that are specific to India, such as special Indian driving cycles and climatic conditions. In addition, low-sulfphur fuel must be available two years prior to the introduction of new standards, so that two validation cycles are possible. Adblue must also be available nationwide in good time, so that DeNOx systems can be validated.

"Of course, there are major challenges for petrol as well. For example, there are currently insufficient quantities of high-octane gasoline (95 RON), which will make additional development efforts necessary and lead to further disadvantages in fuel consumption and CO2. ”

BS VI by 2020 a challenge but achievable

Commenting on the Indian government’s decision to skip BS V norms and leapfrog to BS VI by the year 2020, Dr Heyn said: “Implementation of systems for EU5 and EU6 norms in other countries has taken about four years for each step. In India, jumping directly from BS IV to BS VI within four years will be a big challenge.

"I want to emphasise that Bosch as a company will do everything we can to help the automotive industry meet this challenge. Bosch fully supports the Indian government’s ambitious program to introduce BS VI in one step. As a technology leader in diesel and gasoline engine management systems, Bosch is committed to developing and introducing state-of-the-art technologies for reducing both particulate and NOx emissions as well as CO2 and fuel consumption.”

Also read: Exclusive Interview with Dr Markus Heyn

RELATED ARTICLES

Rajiv Bajaj reappointed MD and CEO of Bajaj Auto for five-year term

Bajaj Auto’s Board of Directors has approved the re-appointment of Rajiv Bajaj as the company’s MD and CEO for another f...

JSW MG Motor launches Comet EV Blackstorm edition

The key highlights of the Comet EV Blackstorm, which is now the top-end variant, are its ‘Starry Black’ exterior along w...

Maruti Suzuki begins production at new Kharkhoda plant

Phase 1 of the Kharkhoda plant will have an annual production capacity of 250,000 units and produce the Brezza compact S...

By Autocar Professional Bureau

By Autocar Professional Bureau

02 Feb 2016

02 Feb 2016

4434 Views

4434 Views

Ajit Dalvi

Ajit Dalvi