ZF ends production of 6-speed auto transmission

The last six-speed automatic transmission for passenger cars rolled off the assembly line in the Saarbrücken plant in Germany last month, delivered for a Jaguar model.

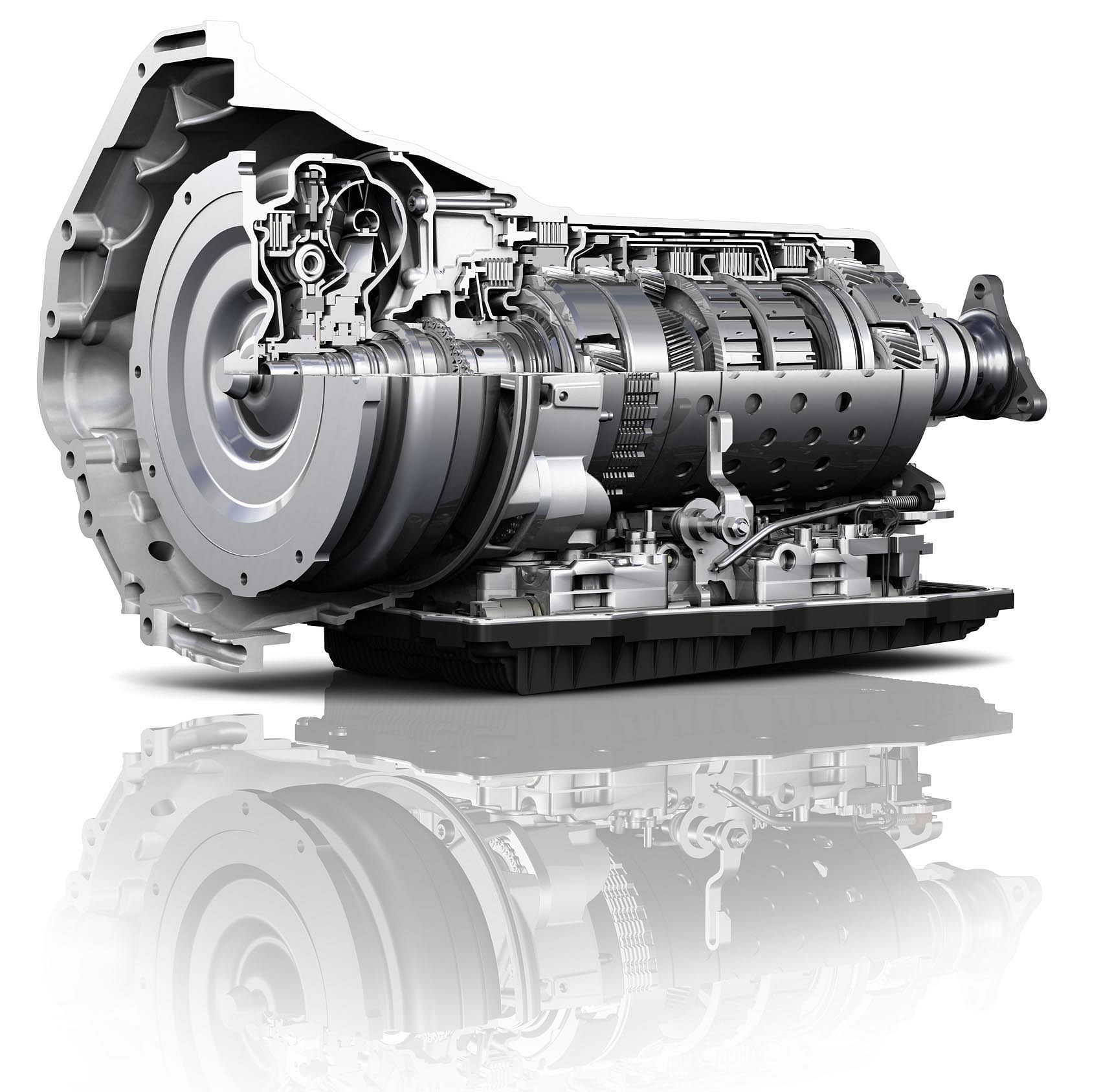

The last six-speed automatic transmission for passenger cars rolled off the assembly line in the Saarbrücken plant in Germany last month, delivered for a Jaguar model. Over the past 13 years, over seven million units of the 6HP have been produced at the ZF location in Saarbrücken over the last 13 years.

However, the ZF transmission plant in Shanghai will continue to produce the 6HP for the Chinese markets

Its successor model with eight speeds has continued this success story since 2008.

Over its production period, the 6HP, which had a development time of only four years, set several landmarks. As the first six-speed automatic transmission for passenger cars worldwide, it caused a stir within the entire industry when it was launched in 2001 before it quickly became a million-fold bestseller offered in many versions.

Its benchmark data was that it was 13 percent lighter, up to 7 percent more economical, with significantly reduced noise levels, and delivered considerably better acceleration values than its predecessor with five gears

More than seven million

After a production time of almost 13 years, ZF has counted exactly 7,050,232 units of its six-speed automatic transmission for passenger cars. "The demand for this innovative transmission has grown very quickly and very strongly which enabled us to win more and more customers and conquer new vehicle segments," said Michael Hankel, member of the ZF Board of Management and responsible for Car Powertrain Technology and Car Chassis Technology. "During peak periods, we produced up to 4,500 units of the 6HP in a three-shift operation; the annual record lies clearly above one million". Also the transmission's further development contributed to its ongoing strong demand. Starting from 2006, the 6HP scored additionally with response times below the human perception threshold and further fuel saving potential between three and six percent. During the entire production time, 16 different automotive manufacturers have employed this transmission and have equally installed it in their luxury cars, SUVs, midsize convertibles, and sports cars. In order to cover this wide application spectrum, 11 variants of the 6HP were available – customised for the respective driveline setup and torque requirements between 230 and 750 Nm.

Following in the tradition of the 6HP, ZF’s second generation of the 8-speed automatic transmission by (8HP) is now setting new standards in efficiency and shifting performance.

The 8HP offers advantages which go far beyond the two additional gears; ZF currently produces approximately 8 800 units per day for automotive manufacturers worldwide: "The first generation was already designed as a flexible modular system; its weight was reduced, it was capable of start/stop operation and allowed to reduce fuel consumption by up to 11 percent compared to the 6HP," said Hankel said.

With the 8HP full hybrid variant, fuel efficiency has been increased by an additional 25 percent. Meanwhile, in July 2014, ZF started volume production of the next 8HP development level. "Thanks to numerous optimisations, the second generation of the 8HP assists our customers even more effectively in meeting the increasingly stringent legal CO2 standards – and it does so in a cost-efficient way as it is combined with standard or hybridised drive systems," Hankel concluded.

Photograph (Top): After a production run of 13 years and more than seven million units, ZF manufactured the last 6-speed automatic transmission (6HP) for cars in Saarbrücken in March 2014.

Photograph (above): Production for ZF’s generation two of the 8-speed automatic transmission (8HP) that has been available since 2008 began in mid-March 2014. It contributes significantly to making standard or hybridised drivelines even more efficient.

RELATED ARTICLES

Horse Powertrain reveals hybrid conversion for electric cars

Engine-making joint venture of Geely and the Renault Group announces new hybrid powertrain that fits into the same space...

Aisin to produce hybrid motor for Mitsubishi in Thailand

The hybrid drive motor and gearbox, will be produced at Aisin Powertrain (Thailand) Co for use in the Mitsubishi XForce ...

GM reports strong Q1 sales in China, demand for EVs and hybrids surges 53%

General Motors and its joint ventures in China have sold more than 442,000 units between January and March 2025.

01 Apr 2014

01 Apr 2014

5140 Views

5140 Views

Autocar Professional Bureau

Autocar Professional Bureau