NSK develops ball bearing for fan clutches with excellent sealing performance

Company says improved reliability delivered by proven sealing performance.

The Tokyo-based NSK Ltd has developed a ball bearing with an excellent sealing performance for fan clutches1used in automobile engines. This product, which features a modified seal that delivers superior performance, contributes to higher fan clutch reliability in markets with harsh driving environments. NSK is targeting sales of 500 million yen in global sales of this product in 2020.

As is known, a fan clutch is a part incorporated into the engine’s cooling fan. It has the ability to temporarily interrupt the driving force of the engine, maintaining the optimal temperature of the automobile engine, thereby improving engine efficiency.

Development background

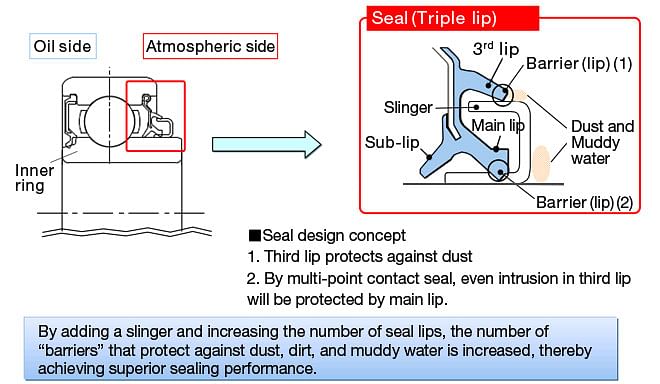

Fan clutch bearings are constructed such a way that one side is sealed by a sealed fan clutch oil and the other side is exposed to atmospheric side which is desired to prevent intrusion of dust, dirt and muddy water. Current fan clutch bearings, by giving preference to integrity both sides are installed by oil sealing seal.

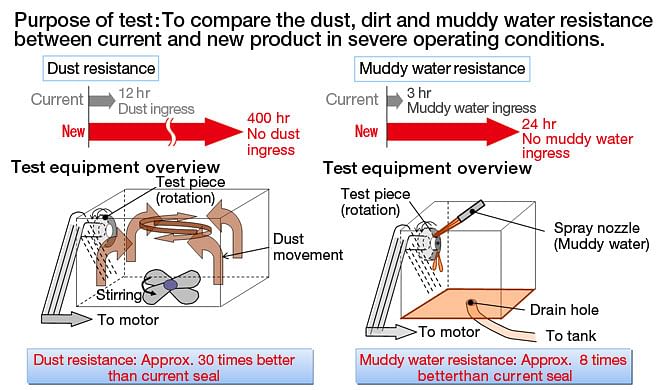

In recent years, automobiles have been used in severe environments, which gather a large amount of dust and muddy water and cause increased seal wear. In the wear progressed region, dust and muddy water enters into the bearing interior and causes abnormal noise. This phenomenon has resulted in a demand for a high dust and high muddy water-resistant seal on the atmospheric side of the bearing. NSK placed a slinger (a circular metal parts pressure-fitted on the inner ring of the bearing) on the inner ring of the bearing and added a triple-layer seal lip to create a fan clutch bearing with excellent sealing performance.

Product features

According to NSK, this product helps achieve superior sealing performance as it has 30 times more dust resistantance and is eight times moremuddy water resistant compared to the previous model. By adding a slinger, which was not used in the previous product, it increases the number of seal lips, the number of ‘barriers’ that guard against dust and muddy water, thereby achieving superior sealing performance. This product contributes to great fan clutch reliability and thereby achieves improved automobile reliability in markets with harsh driving environments.

RELATED ARTICLES

US tariffs will hurt both automakers and US manufacturing: ACEA

European Automobile Manufacturers’ Association says that the EU and the US must engage in dialogue to find an immediate ...

Trump levies 25% tariff on all cars imported to US

President Donald Trump claims new levy on all cars and car parts shipped into the country will create "tremendous growth...

Hyundai opens its third factory in the US: Metaplant America

Hyundai Motor Group Metaplant America's vehicle assembly and battery plant is the key pillar of the Hyundai Motor Group’...

By Autocar Professional Bureau

By Autocar Professional Bureau

22 Dec 2015

22 Dec 2015

5414 Views

5414 Views