Marquardt’s cell module controller optimises battery power, protects against failures

New Cell Module Controller for automotive, truck and cell manufacturers, which Marquardt is presenting at the Battery Show in Stuttgart in June, monitors each individual battery cell in real time

Batteries are at the heart of every electric vehicle. Marquardt has developed a new Cell Module Controller (CMC), which it is presenting at the Battery Show in Stuttgart (June 18-20). The CMC monitors each individual battery cell in real time. The master control unit can thus process data to optimize battery performance and protect against failure. In addition to mobile applications, the CMC can also be used in stationary energy systems.

Imbalances such as deep discharge, overcharging and temperature peaks are important parameters that need to be monitored in lithium-ion batteries to ensure safety. The CMC controls this by monitoring each individual cell and providing important data on the condition and performance of the battery. In the event of problems, the controller informs the master control unit, which in turn decides what to do: charge, cool down or rebalance.

The balancing is necessary, for example, if some of the hundreds of cells that make up a battery are not fully charged. This leads to imbalances and the uniform cell voltage in the battery pack is lost. Such scenarios are prevented by real-time control and monitoring. The CMC optimises the operating status, protects against overcharging and overheating and increases the safety and longevity of the battery. The control unit thus reduces the likelihood of battery failure and prevents the high costs associated with replacement. In the long term, this results in considerable savings potential.

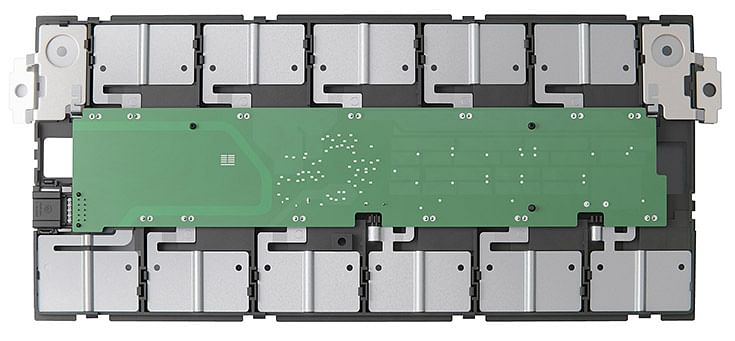

The Cell Module Controller including a cell contacting system can be attached directly to the cells and welded to the battery pack.

The Cell Module Controller including a cell contacting system can be attached directly to the cells and welded to the battery pack.

Scalable and easy to integrate

Marquardt’s Cell Module Controller is compatible with a wide range of battery chemistries and form factors. Analog front ends (AFE) without software dependencies serve as a communication interface to other electronic control units (ECUs) in the system, making the CMC versatile and easy to integrate.

The CMC therefore offers maximum flexibility for car, truck and cell manufacturers. In addition to the automotive sector, it is also suitable for integration into stationary battery systems. The design is scalable and is constantly being updated to meet evolving industry standards and customer requirements. For instance, Marquardt states that it is working on wireless variants of the Cell Module Controllers that aim to improve the adaptability and installation efficiency of the system and offer even greater flexibility and ease of use in various applications.

Marquardt will be providing further information at the Battery Show from June 18 to 20 in Stuttgart.

Marquardt-CMC-incl.-Cell-Contacting-System.jpg

RELATED ARTICLES

Horse Powertrain reveals hybrid conversion for electric cars

Engine-making joint venture of Geely and the Renault Group announces new hybrid powertrain that fits into the same space...

Aisin to produce hybrid motor for Mitsubishi in Thailand

The hybrid drive motor and gearbox, will be produced at Aisin Powertrain (Thailand) Co for use in the Mitsubishi XForce ...

GM reports strong Q1 sales in China, demand for EVs and hybrids surges 53%

General Motors and its joint ventures in China have sold more than 442,000 units between January and March 2025.

By Autocar Professional Bureau

By Autocar Professional Bureau

24 May 2024

24 May 2024

1649 Views

1649 Views