Audi's eco-friendly measures save up to 500,000 cubic metres of fresh water a year

In conjunction with the existing treatment plant, the premium manufacturer will in the future recycle about half of the wastewater produced at the Ingolstadt site.

German car maker Audi has reported reaching another milestone on its way to wastewater-free automobile production. The company has put a new service-water supply centre into operation at the Ingolstadt plant.

In conjunction with the existing treatment plant, about half of the wastewater produced at the site can now be recycled and treated for reuse. In this way, Audi will saves up to 500,000 cubic metres of fresh water each year. The heart of the service-water supply centre is the so-called membrane bioreactor (MBR).

Water is necessary in the entire manufacturing process of an automobile, for example in the paint shop. With the new service-water supply center, Audi is going new ways at the Ingolstadt site and making even more efficient use of water as a resource.

“Thanks to this innovative wastewater treatment system, we are reducing the fresh-water requirements of production at the Ingolstadt plant by a third,” says Rüdiger Recknagel, Head of Environmental Protection at Audi AG. “At the same time, we are avoiding approximately 40 percent of wastewater.”

This underscores the premium manufacturer’s commitment to the sustainable use of water: At its Mexican plant in San José Chiapa, Audi has been producing cars without wastewater since 2018, as certified by independent experts. With the new supply center, the plant in Ingolstadt has also reached a milestone along the way to zero liquid discharge (ZLD).

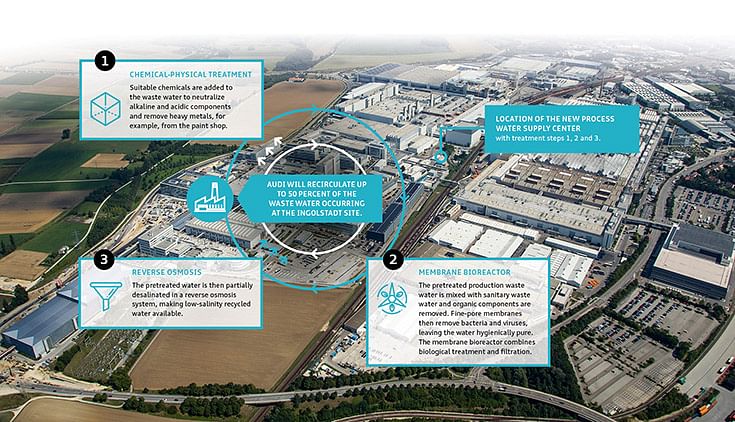

Three-stage treatment

Before the company returns the wastewater as fresh service water to the production processes at the Ingolstadt plant, it is treated in up to three stages. It first passes through a chemical-physical process. This neutralises alkaline and acidic components and removes heavy metals, for example from the paint shop. The membrane bioreactor is then used. It is the core element of water treatment. Here the production water is mixed with sanitary wastewater and freed from organic components. The MBR then removes bacteria and viruses from the wastewater using pore-fine membranes. Audi is thus taking water treatment one step further than conventional sewage treatment plants that do not use this process. Finally, reverse osmosis removes residual salts. The treated wastewater is then returned to the production process as service water.

With the new service water supply centre, Audi will save up to 500,000 cubic metres of fresh water each year. In conjunction with the existing treatment plant, the premium manufacturer will in the future recycle about half of the wastewater produced at the Ingolstadt site.

In order to save groundwater, Audi is also increasingly using rainwater for service water purposes at its Ingolstadt plant. Rainwater from over 450,000 square metres of roof and parking space is collected in underground cisterns. Depending on weather conditions, up to 260,000 cubic metres of rainwater can be used annually.

Audi has set itself the target of reducing the environmental factors of energy, CO2 emissions, fresh water, waste and volatile organic compounds by 35 percent per car produced by 2025 compared with reference year 2010. The company’s long-term goal is to produce automobiles that are CO2 neutral and wastewater free.

RELATED ARTICLES

Horse Powertrain reveals hybrid conversion for electric cars

Engine-making joint venture of Geely and the Renault Group announces new hybrid powertrain that fits into the same space...

Aisin to produce hybrid motor for Mitsubishi in Thailand

The hybrid drive motor and gearbox, will be produced at Aisin Powertrain (Thailand) Co for use in the Mitsubishi XForce ...

GM reports strong Q1 sales in China, demand for EVs and hybrids surges 53%

General Motors and its joint ventures in China have sold more than 442,000 units between January and March 2025.

By Autocar Professional Bureau

By Autocar Professional Bureau

21 Mar 2019

21 Mar 2019

7265 Views

7265 Views